In June 2023, Catherine was invited to present a paper session at the SSAC 2023 Conference in Calgary, AB, on the topic of concrete conservation in the National Capital Region. This year’s SSAC conference’s theme was Cast-In-Place, exploring the impact of concrete on Canada’s built environment. The theme brought sessions beyond concrete, reflecting on multidisciplinary frameworks that challenge preconceived definitions of what constitutes a sense of place.

In collaboration with Professor Mariana Esponda from Carleton University, Catherine’s presentation outlined on-going research related to concrete construction in the context of Ottawa, ON. Mariana and Catherine first embarked on this research topic as part of a MITACS accelerate grant in 2020 while Catherine completed her Master of Architecture at Carleton University. Since then, Catherine and Mariana have joined forces, approaching the topic from both academia (Carleton University) and practice (TRACE architectures) as they continue to investigate the use and evolution of the material in the Ottawa-Gatineau region.

EARLY CONCRETE

Concrete in Ottawa holds historic, aesthetic, economic and technological values as an innovative construction technique of the twentieth century. These values represent Ottawa’s identity and its function as the country’s seat of government. Observing the beginnings of concrete, we can begin to understand its history that led to it becoming the material of choice for building the nation’s capital. This why came from our curiosity of the material’s history but also the scope of work of recent building rehabilitations using various forms of cast-in-place and precast concrete. Other Canadian cities are known for steel and brick, could Ottawa be known for concrete?

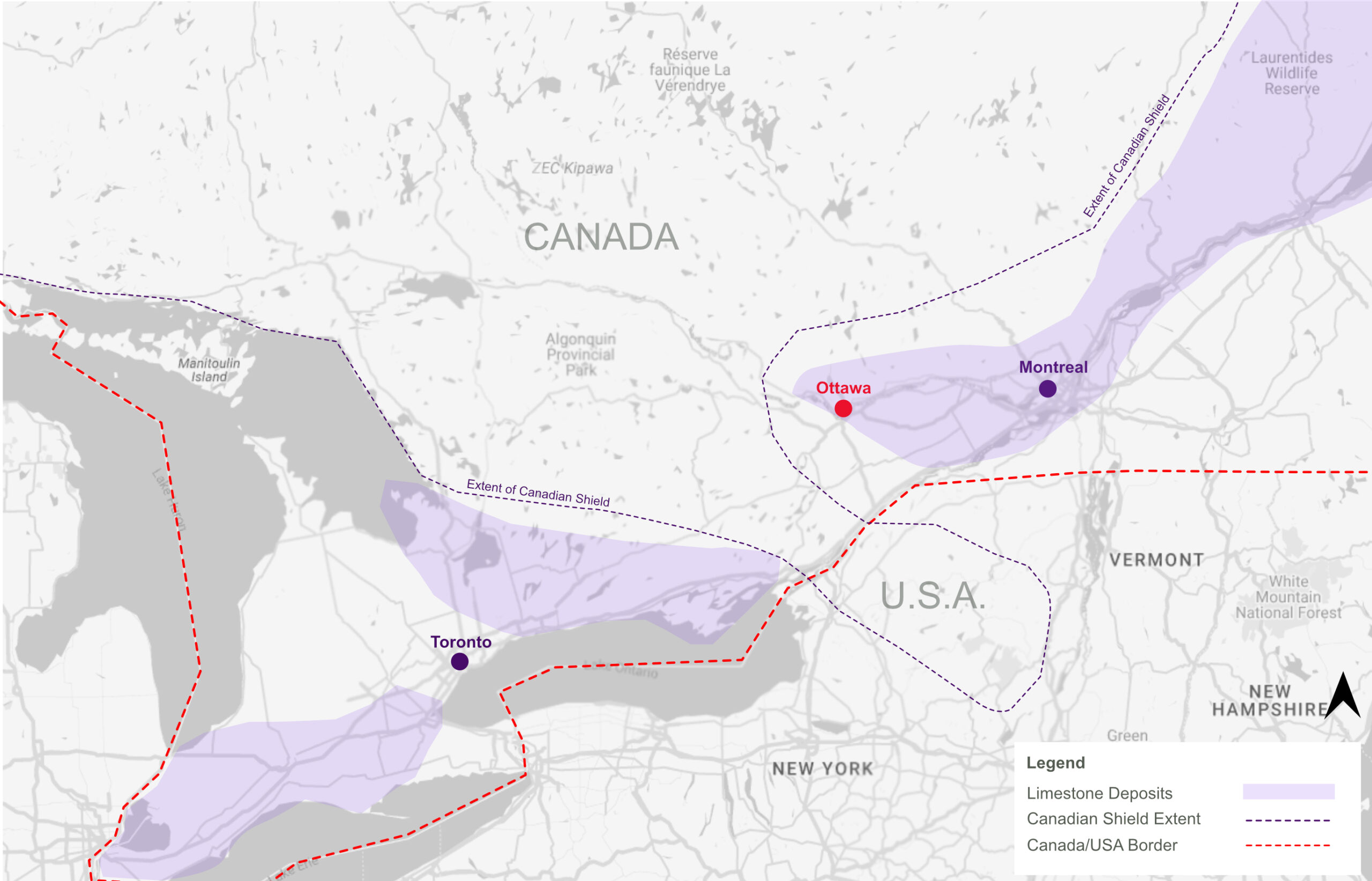

The answer was perhaps in the geology. This map shows the location of Ottawa and known areas of limestone deposits, just outside the limits of the Canadian Shield. This limestone is the primary ingredient in most of Ottawa’s concrete.

Concrete in Ottawa started as one of its ingredients: cement. The late 1880s was a time for experimentation for natural cements until the 1890s once Portland cement was deemed stronger. Interestingly, the development of cement plants in Canada coincided with the first 30-50 years as a commonwealth country.

As the industry developed, the use of marl for Portland cement was improved and was replaced with limestone, allowing for more extraction opportunities that were not limited to the few locations where marl could be found. Limestone extraction plants developed near populous cities including Toronto, Ottawa and Montreal where the market and transport of the material was best suited for cement production. The local production of Portland cement consisting of a mix of local sand and stone, grew coincidentally with the requirements of a developing nation and used in a variety of construction projects to build Canada’s capital.

Carbide Willson Mill, Meech Lake, QC

An example of early twentieth century cement mixtures making use of structural reinforcement includes the Carbide Willson Mill near Meech Lake in Chelsea, Quebec. Built as a powerhouse and acid condensation plant to develop Phosphorous Acid in 1911, the dam and generating plant fell into disrepair following a production limit and the tower was ruined in a fire, leaving the base, dam and generating plant in state of ruin.

What makes this case study important when considering concrete conservation in Ottawa is to recall the roots of the use of the material, which initially was a low-cost and easily accessible material for industrial-use buildings. From a conservation perspective, it is important to consider just how robust even the earliest forms of concrete are compared to other types of construction, notably masonry or wood.

Pivoting to the use of concrete in the mid-20th century, we see an example of the realities and future of existing concrete buildings in Ottawa. Concrete in the mid-20th century focused on the rapid technological advancements of the material that pushed its plastic qualities to perform in a variety of new casting techniques.

Lester B. Pearson Building, Ottawa ON

The Lester B. Pearson Building, designed by WZMH, is a classified Federal Heritage building that was designated for its high-quality design and in part due to its technical achievement of using a ‘c’ shaped precast concrete panel. The building sits neatly within its surroundings along Sussex Drive and its local granite aggregate gives the building its warm hues.

As of 2017, TRACE has been a part of a significant rehabilitation program including an extensive conservation plan to protect its high heritage designation status. Part of the conservation approach was to repair the existing precast panels.

The ‘Shockbeton’s’ technology, done by vibrating or ‘shocking’ the concrete to increase its strength, was used for the precast architectural panels at the Lester B. Pearson Building. Constructed in 1973, the building uses 3-dimensional ‘c’ shaped panels for elements such as cladding, planters, and pavers, all of which are part of the character defining elements of the building.

Informed Conservation Approaches

What this research has shown is that concrete conservation is not as straightforward as other historic materials we know and have developed extensive conservation processes for. The reality is that concrete is not yet completely understood and is still relatively young.

This is where understanding the history of concrete specific to a geographic area is important. The material can react differently depending on its weather, loading conditions, and construction detailing.

Generally, concrete and salt do not agree with each other, and Canada’s de-icing techniques can be detrimental to concrete. While this may manifest visually for materials like sandstone or limestone, salt can contribute to rust jacking and rebar corrosion below the concrete’s surface making its conservation process less straightforward.

We must also consider that concrete used in the 20th century is in most cases the byproduct of an experimental building material constantly evolving and used in a variety of casting and forming techniques. This means that not all buildings that use the same category of concrete will be the same.

Grappling with Reality

We are already seeing the need for retrofitting large office complexes with immense quantities of concrete in various forms. Generally, interest and willingness to conserve existing concrete is client driven—an option that appears less favourable when we consider the embodied energy of new and existing building materials.

We also need to come to terms with the sheer quantity of concrete in Ottawa. Like many north American cities, the post-war construction boom and megastructures influence has left us with buildings that would simply not be built the same today if constructed new. The influence of brutalism and the megastructures movement have contributed to many buildings that have shaped a collective identity of what constitutes Canadian Architecture. With a growing appreciation for their design values, we can expect many concrete buildings to approach a need for intervention.

Avoided Carbon 🤝 Concrete Reuse

What we do know, however, is that cement (concrete’s primary ingredient) accounts for 6-10% of Global Carbon Emissions (Architecture 2030). Studies have also confirmed that retrofitting existing buildings can reduce 70% of energy use compared to new builds. These two numbers combined make the case for favouring retrofits over building new.

What we are seeing in Ottawa is much of the city’s building stock, constructed during the modern period, nearing the end of its lifecycle. Combined with a city struggling to fill a downtown core in a post-pandemic reality, existing buildings are looking for new ways to stay relevant.

From a sustainability perspective, we simply cannot make the case for demolishing existing buildings to replace with new materials and contribute to landfills. At this rate, we must consider making-do, but most of all recognizing the value embedded within our existing buildings that in many instances explored new design developments, schools of thought, and building materials.

Concrete of the Future

However, the use of concrete in future buildings is less than likely to be replaced by another material. This means we need to collectively research alternative ways of producing the material with lower environmental impacts, such as carbon sequestration. A recent article by Ken Grafton, outlines various new technologies that can help make the way we produce concrete today more sustainable. Nova Scotia based Carbon Cure has developed a way to capture existing CO2 (produced by the fossil fuel industry), by changing its state from gaseous to solid and embedding it within the concrete mixture, diverting it from the atmosphere. The resulting chemical reaction of cement, water, and carbon dioxide, produces CaCO3 (Calcium Carbonate), which improves the compressive strength of the concrete.

As a known contributor of carbon, concrete production for building Canada’s capital is responsible for a significant amount of embodied carbon. These concrete buildings are coincidently approaching a nearing vintage that will require significant rehabilitation and material-specific conservation. While concrete remains the material of choice for buildings faced with the Canadian climate, there lacks further research into how the material can be used in ways that are inherently more sustainable.